EST Group Products Pop A Plug System

Pop A Plug System

No one knows pipe and tube plugging better than Expansion Seal Technologies. Since 1968, we’ve specialized in the design and production of innovative, high quality plugs and installation tools for a wide range of pipes and tubes. And along the way, we’ve earned

a reputation for outstanding workmanship, tireless attention to detail, and dedicated customer service.

At Expansion Seal Technologies, we offer a depth of experience and expertise that other companies would find hard to match. No matter what your plugging problem, our experts can provide you with the assistance you need, when and where you need it.

We’re also iso-9001 certified, so you know the products you’re getting are up to the highest quality standards. And we’ll also get them to you fast, so you’ll always have what you need, when you need it.

POP-A-PLUG® P2 HIGH PRESSURE TUBE PLUGS

Repair Heat Exchanger Tube Leaks without Welding

When it comes to heat exchanger maintenance for shell and tube condensers and boilers, you need a tube plugging solution you can rely on.

Pop-A-Plug P2 High Pressure Tube Plugs provide a permanent mechanical tube plugging solution for leaking heat exchanger tubes without welding, eliminating potential circumferential cracking and other heat related issues associated with welding.

EST Group’s high-pressure tube plugs maximize uptime by maintaining a helium leak-tight seal that will not eject like friction fit tapered plugs. Pop-A-Plug Tube Plugs ensure stability through a ring/pin design with metallurgy matched to tube material to minimize thermal expansion/contraction issues, and undesirable galvanic corrosion. No welding required.

Pop-A-Plug P2 High Pressure Tube Plugs provide a long-term solution that allows you to plug heat exchanger tube leaks confidently!

Pressure Rating

Up to 7,000 PsiG (483 BarG) - higher pressures available upon request

Size Range

0.400” to 1.460” (10.16mm to 37.08mm) Tube I.D. - larger/smaller sizes available upon request

Standard Materials

Brass 360/464, Carbon Steel (1018 & 1045), 304/304L Stainless Steel, Copper Nickel 70/30, 316/316L Stainless Steel, Titanium – additional alloys available, contact customer service for full list

Features & Benefits

- Maximizes plant uptime by combining ease of installation and long term performance

- Engineered breakaway controls installation force preventing damage to the tube, tubesheet, and surrounding tubes

- Maintains helium leak-tight seal to 1 x 10-10 cc/sec

- Meets ASME PCC-2* recommendations and EPRI** criteria

- Accommodates Through-the-Tube Plugging applications

- Simple hydraulic installation takes only minutes

- Lowest lifecycle cost compared to alternative tube plugging methods

- Ideal for use in applications with coated tubes and tubesheets

- Large inventory available with 24/7 emergency manufacturing capability

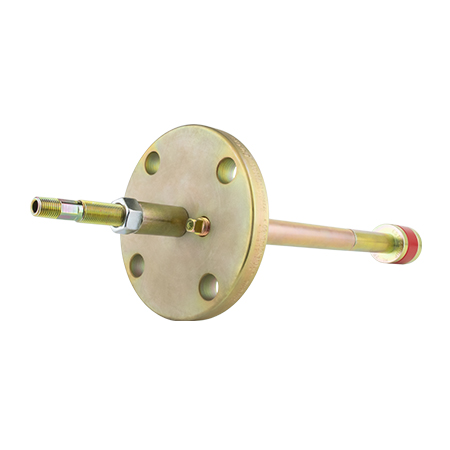

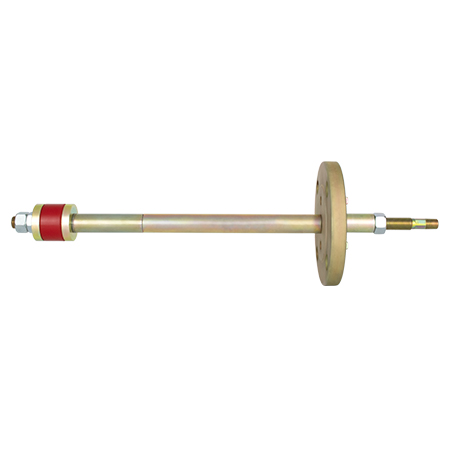

HIGH LIFT FLANGE WELD TEST PLUG

Purge, Weld, and Test Flange Connections with One Plug

Reduce the expense, downtime delays, and waste disposal problems associated with conventional flange-to-pipe weld testing with EST Group’s High Lift Flange/Weld Test Plug. High Lift Flange Weld Test Plugs allow you to monitor upstream conditions, isolate and purge the weld area, perform the weld, and hydro test weld joint to ANSI B16.5 requirements using only one tool. No blind flanging upstream, no vacuum truck for evacuating the line, and no X-raying. Each flange test requires a minimum amount of water, eliminating the need to fill the entire line. Use less water and minimize your environmental impact!

Size Range:

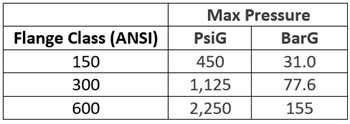

3/4" – 24” NPS (DN20 to DN600)

Flange classes 150# to 600#

Higher flange classes available upon request

Standard Seal Material:

Urethane – alternative materials available upon request

Features

- Improved seal-to-pipe Clearance: plug can be easily installed and removed even where there is severe weld protrusion

- Flange-to-pipe welds are tested without pressurizing the entire system

- Ported center shaft allows for upstream monitoring

A flange hydro test plug allows you to monitor upstream conditions, isolate and purge the weld area, and perform the weld with only one tool.