Flame Arrester

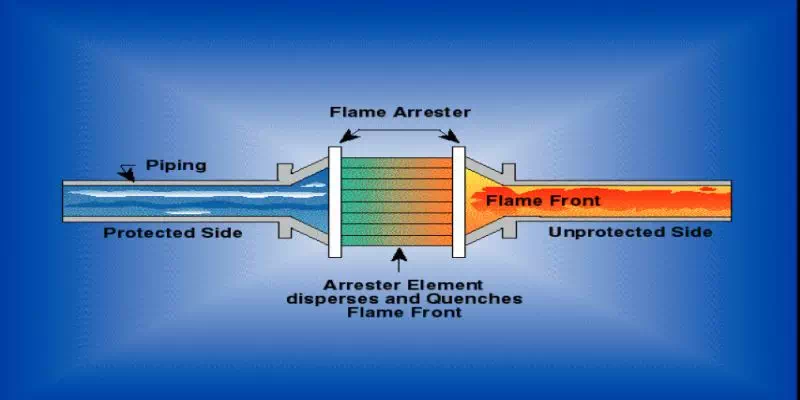

Function

- Flame Barrier

- Flame Holder

- Dissipates Heat

Principle of Flame Arrester

- Dissipates Heat

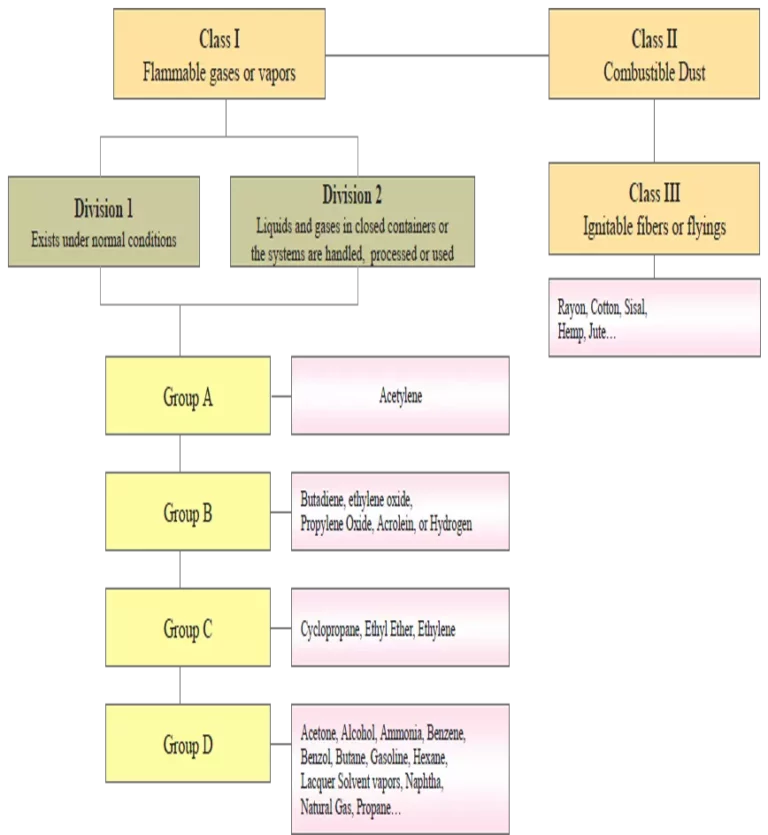

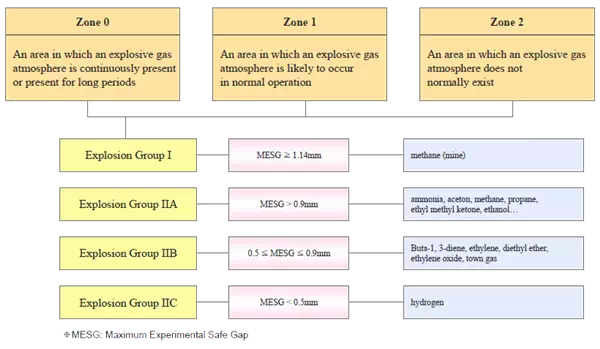

- Gap of Flame Element MESG of Chemical

MESG: Maximum Experimental Safe Gap *For example, MESG of propane is 0.965mm.

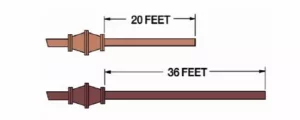

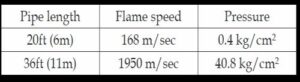

Example of Detonation Flame Arrester

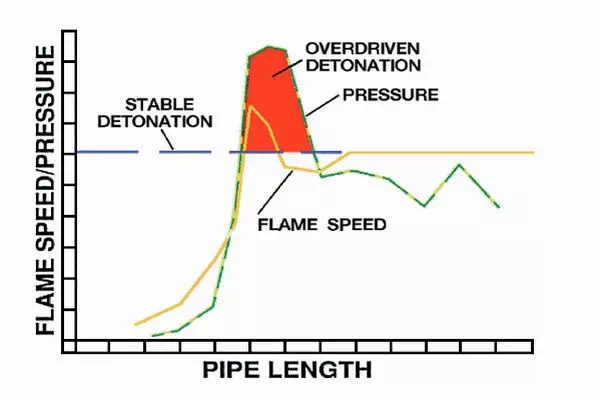

Effect of run-up length on pressure and flame

Basic information for ordering flame arrester

- Kind of mixture of gases or vapors, and their concentrations

- Type (End-of-line/In-line, Deflagration/Detonation)

- Maximum operating pressure

- Normal operating pressure (if possible)

- Operating temperature ranges

- Normal operating temperature (if possible)

- Size and connection (ex, 4” – JIS 10K Raised Face Flange)

- Material of body and flame element

- In case of in-line type, configuration of pipe system and dimensional information (Deflagration Flame arrester should be installed at nearest position from potential ignition source. We recommend it must be installed within 20 times of pipe diameters of the open end of the vent pipe or the potential ignition source.)

- Acceptable pressure drop at flame arrester

- Set pressure, vacuum (for flame arrester with integrated pressure/vacuum relief valve)

Effect of pipe length on pressure and flame speed

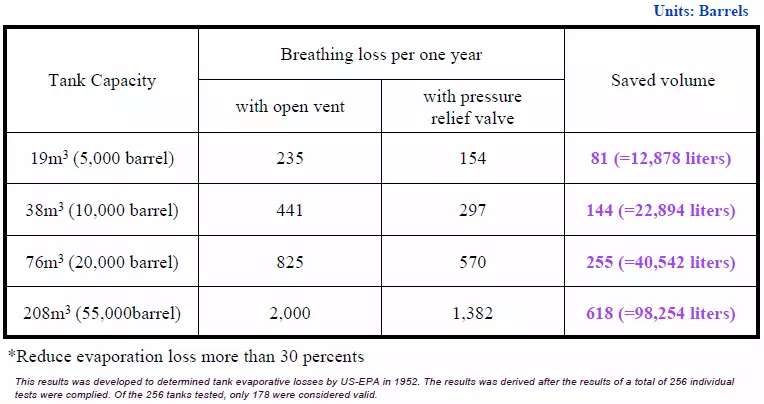

Breathing Loss Comparison Table

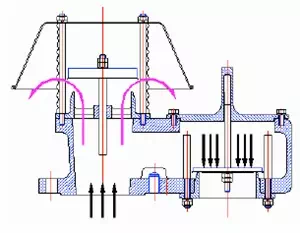

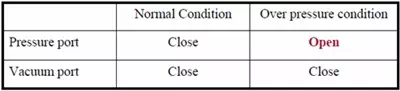

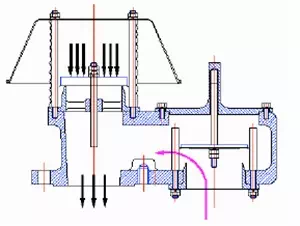

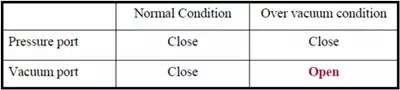

Pressure Relief

Basic Requirements of Relief Valve

- Anti-corrosion to the handling chemical

- Maximum venting capacity of valve

– Normal venting requirement

– Thermal venting capacity

– Other venting requirements due to chemical reactions, internal or external heat transfer device, etc.

※ These requirement are specified in API 2000 Standard. - Sealing

Basic information for ordering pressure/vacuum relief valve

- Kind of chemical, their concentrations and physical status

- Type (Pressure relief, vacuum relief, pressure and vacuum relief)

- Storage tank capacity

- Design pressure and/or design vacuum of storage tank

- Normal operating pressure/vacuum of storage tank

- Set pressure and/or set vacuum of relief valve

Emergency Venting Device

- Emergency Venting for Tank subject to Fire Exposure

- Secondary Safety Device for Emergency

- Large sized and High Capacity

- Access for Maintenance (Large sized model)

Vacuum Relief

Causes of Overpressure or Vacuum

- Liquid Movement into or out of a Tank

- Weather Change

- Fire Exposure

- Utility or System Failure

(Internal or External Heat Transfer Device, Venting device etc.,) - Other Circumstances

- Maximum filling rate

- Maximum discharging rate

- Insulation thickness of storage tank

- Size and connection (ex, 4” – JIS 10K Raised Face Flange)

- Materials of body, seat, pallet, and diaphragm

- Other information and specification to be considered

General Specification

- Size : 18”, 20”, 24”

- Connection : API 650 or ANSI Class 150lb Flange

- Materials : Carbon Steel / Aluminum / Stainless Steel

- Maximum working Pressure & Set pressure : Determined by

- API Standard 2000

*API: American Petroleum Institute